Hoffman

Consultants

Hoffman

ConsultantsStructural Engineering

& Detailing

|

Cold-Form Metal Framing (Metal Stud) Engineering and Shop Drawings

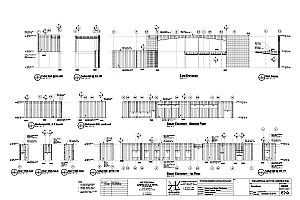

Hoffman Consultants are experts in the design and assembly of metal stud framing. We utilize the latest software to create easy to read and complete sets of metal stud shop drawings. Our drawings include plans, elevations, sections and 3D isometric drawings to help our clients easily comprehend and build their projects.

If you are interested in recieving a quote for metal stud shop drawings, send the architectural and structural drawings, along with the 5400 specification to: quotes@hoffmanconsultants.comExample Metal Stud Shop Drawings:

Metal Stud Framing FAQ:

- Why is it required to have engineered shop drawings?

- Are drawings required for all studs?

- What is a deflection clip?

- Will lighter studs always save money?

- Do I always need a supplemental clip for each connection?

- How much deflection space is enough?

- Is bridging required in all walls?

- How are stud sizes called out or designated?

- Is it important to follow the shop drawings in construction?

- Do wood studs and metal studs basically behave the same during construction?

- The contract specifications for my project require a shop drawing submittal with calculations prepared by a Professional Engineer. How do I go about getting shop drawings prepared?

- What is the use of metal stud shop drawings if they are not required in the specification?

- Are special inspections required for metal studs?

- Why is it required to have engineered shop drawings?

In most cases the engineer of record only checks the main stud required. This is based on the height, wind speed and exposure, and the type of material being supported. The supply side (Hoffman Consultants) engineer uses that information to specify fasteners, assemblies, and layout of studs for the entire project. Let's look at an example.

- The height is the unsupported length between anchor points. In most cases the unsupported length is the distance between the floor and the next story or roof. If the stud is anchored in between somewhere the height is the distance to that point. A common range of height is 8 to 14 feet.

- The minimum required wind velocity applied to most buildings is 115 MPH ultimate or 90 MPH nominally, except at coastlines. Factors are then applied to this wind velocity based on the exposure of the building and the surrounding landscape. The more open the wind path, the greater the applied load. Exposure “C” is commonly used resulting in a 25 - 30 PSF force applied to the components and cladding on the building; e.g. metal studs, windows, or soffit framing.

- The first calculation is to determine the strength of the stud to resist the loads without failure. In addition the materials (cladding) must not fail. The outside materials determine how much bending is allowed in the stud, also known as deflection. Allowable deflection is defined as a ratio of the amount of deflection per the length of unsupported span and expressed as a length divided by a variable. In the case of brick veneer, a ratio of L (length)/600 is required.

For the example, the engineer will first design the stud for strength. The shape, gage, and steel strength must be adequate to support the loads without yielding. The engineer will then determine the allowable inches of deflection next. For 12 feet and brick veneer, this would be 12 x12 / 600 or about ¼ inch, which is not much. He then must calculate the thickness or gage of the stud that will be stiff enough to support the load without exceeding the deflection limits. This calculation determines the main stud depth and gage. The record design engineer will specify the loads and deflection criteria and the stud nominal size on the drawings.

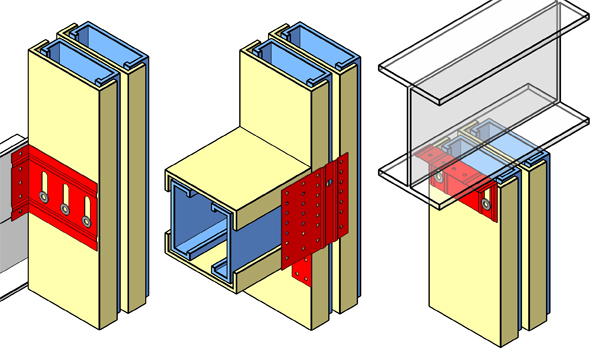

In most cases the engineer of record stops here and specifies shop drawings be provided. Unlike wood studs, metal studs come in vast variety of sizes and gages. The gages affect the capacity of fasteners in addition to strength and serviceability (deflection resistance). All of these variables must be taken into account to proceed with the design. The shop drawings detail how all of the studs will be assembled and anchored to the main structure.

The layout of the building windows and doors is one of the main uses of shop drawings. When the studs are interrupted the loads transfer to headers and sills which spread the loads across to jambs on each side. The shop drawing engineer will determine the assemblies and fasteners required to meet the design requirements. It should be obvious the jambs on either side of an opening will pick up more load and will require more "plies" to meet the load requirements of the drawings and specifications. These are all shown on the shop drawings, but instead multiple studs the fabrications are made up of combination of studs and track.

- Are drawings required for all studs?

Generally only exterior walls, bearing walls, and combinations of both are required to be designed and shown on shop drawings. Interior non-bearing studs are not subject to significant lateral loads and usually support wallboard which is flexible in comparison to brick. An interior stud is thin (20, 22, or 25 gage) while exterior studs are usually a minimum of 18 gage.

- What is a deflection clip?

A deflection clip slides or slips in the vertical direction. It only supports the stud in the horizontal directions. Unless a stud is designed to take vertical load, it will deflect or buckle under compression and fail. The slip connection guards against incidental bearing loads. For example, if a spandrel beam deflects under the floor load, the studs underneath it will pick up the loads unless there is a slip connection at the attachment point.

- Will lighter studs always save money?

Lighter studs will save money most of the time but not all the time. Sometimes there will be an increase in fasteners which will drive up labor costs.

- Do I always need a supplemental clip for each connection?

A regular stud nested in a track generally will not require a clip at the base if the track matches the gage of the stud. Of course it still needs to be anchored to the track at the flanges and the track must be anchored to the floor. Unless it is a bearing wall the top connection will require a slip type connection. Base clips are generally required at the bottom of built up jamb members at doors and windows.

- How much deflection space is enough?

Assuming the dead load is already applied when the wall is built; a safe maximum deflection is the length in inches of the floor span divided by 360. For example at 30 feet, 12 x 30/360 =1 inch

- Is bridging required in all walls?

If both sides of a wall are sheathed they are considered braced against bucking in the weak axis and no additional bridging members are required. For non-bearing walls no additional bracing is specified. On bearing walls Hoffman Consultants will specify bridging at 4 to 6 feet on center vertically. This protects against loading the wall during construction before the sheathing is installed.

- How are stud sizes called out or designated?

Hoffman Consultants utilizes SSMA standards.

Example 1: 600S162-43

600 = 6 inch depth, S = stud member, 162= 1.62 inch flange width,

and 43 = .043 inch nominal thickness.Example 2: 362T125-54

362 = 3.62 inch depth, T = track member, 125 = 1.25 inch flange width,

and 54 = .054 nominal thickness.Sometimes gage designations are used to define stud thicknesses similar to sheet metal standards. 1 mil is equal to 1/1000 of an inch. For example 54 mils is approximately equal to 0.054 inches.

25 gage = 18 mils

22 gage = 27 mils

20 gage drywall = 30 mils

20 gage structural = 33 mils

18 gage = 43 mils

16 gage = 54 mils

14 babe = 68 mils

12 gage = 98 mils

- Is it important to follow the shop drawings in construction?

Once the shop drawings are approved they become the contract drawings for construction. All assemblies and fasteners must be followed or a redesign will be required. Hoffman Consultants will work with their customers to configure stud assemblies in such a way as to maximize the efficiencies of the field construction. These may not match the construction drawings exactly.

- Do wood studs and metal studs basically behave the same during construction?

Metal stud dimensions are similar to wood studs but are quite different in how they are assembled. Metal studs are flimsy and almost worthless without the sheathing bracing the members. Because wood is a solid material it has some stiffness on its own. In wood construction, deflection problems have historically not been an issue, while just the opposite is true with metal studs. Bridging and bracing is extremely important when using metal studs. Metal studs have very little strength in the week axis and are highly susceptible to buckling when used as floor joists and frequently require web stiffeners over bearing points. Professionally prepared shop drawings by Hoffman Consultants will properly detail how each stud is assembled to meet design requirements.

- The contract specifications for my project require a shop drawing submittal with calculations prepared by a Professional Engineer. How do I go about getting shop drawings prepared?

Hoffman Consultants is your one-stop service for professionally prepared shop drawings and calculations for Cold Formed Metal Studs. Just one look at our product is enough to see our quality of drawings is second to none in the industry. In addition to plan and elevation views, Hoffman Consultants will always provide 3D isometrics of stud assemblies in order to clearly portray the assembly configuration. A pace setter in design excellence, Hoffman Consultants has been serving our customers for over ten years in this still emerging industry.

HC will work on a fixed fee or hourly basis depending on what works best for the customer. For a quotation, drawings can be shipped to us by mail or simply send PDF copies by E-mail. A copy of the project specifications is also required.

- What is the use of metal stud shop drawings if they are not required in the specification?

Metal stud shop drawings provide the following benefits:

- Clear description of framing assemblies.

- No over anchoring of members. (too many screws)

- Easy field checking for acceptance.

- 3D assembly reference drawings for configuration.

- All jambs and headers designed for wind load tolerances.

- Cut sheets for bearing walls.

- Bill of material (for added fee, this is not normally included).

- Early identification of field problems.

- Are special inspections required for metal studs?

Special inspections are not required unless dictated by the owner, architect, engineer, building authority or possibly the general contractor. Hoffman Consultants always recommends that a special inspector familiar with the cold formed trades be employed to assure proper design is followed. This starts with a clear and concise set of shop drawings produced under the authority of a qualified design professional.